I caught up with Daniel to discuss his journey as an engineering student and entrepreneur.

Tell us about your work with the Bio-Adhesive Alliance team.

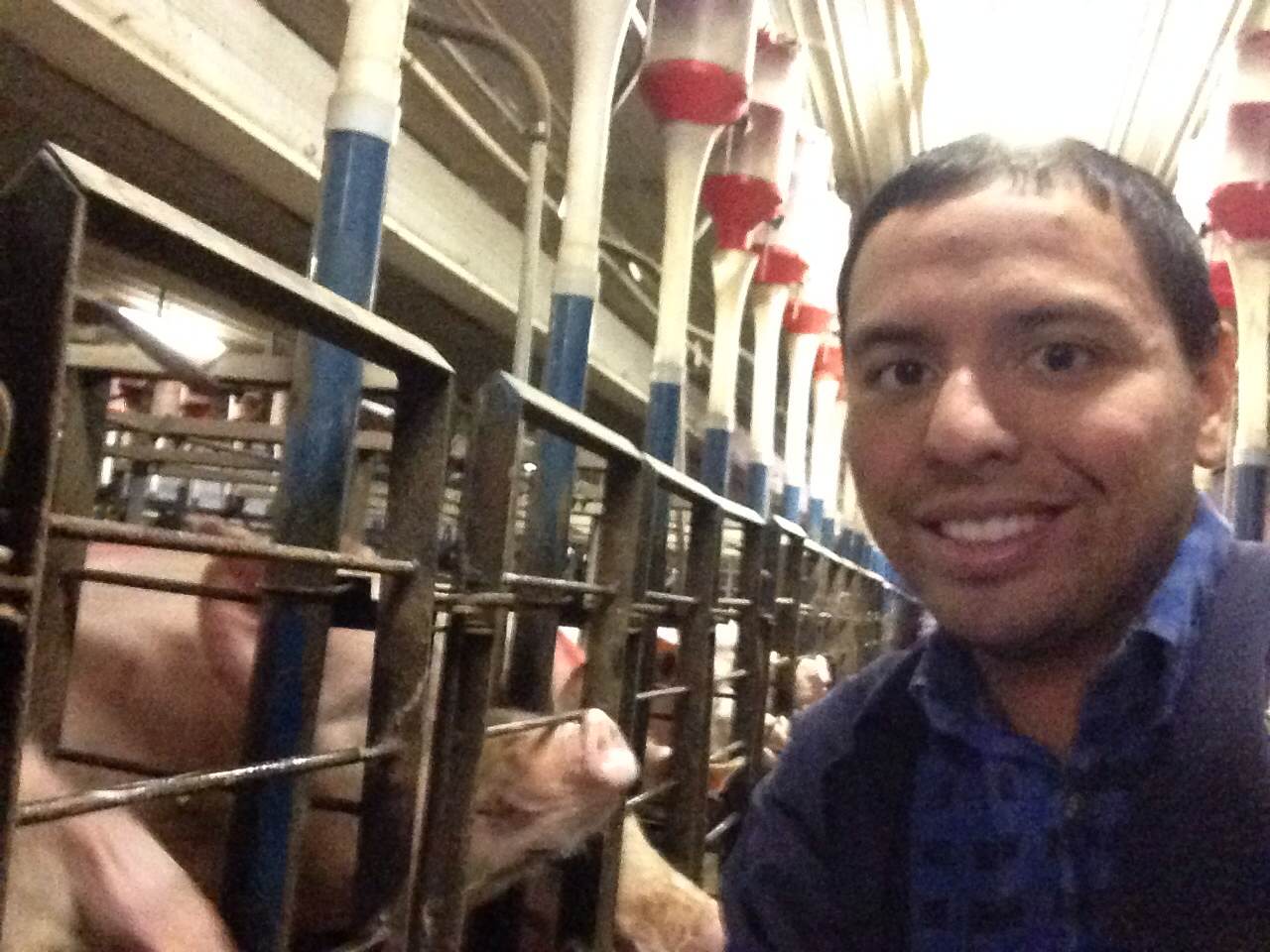

There are 6 billion gallons of manure in the United States. This manure is highly concentrated on large pig farms across United States, in Utah, Pennsylvania, Minnesota, Ohio, and North Carolina, and elsewhere. The steady flow of pig manure is shipped off to farms around the country to spray on fields as fertilizer or for lagoons. It is estimated by some that farms are nine times over-fertilized with manure. Hog farms are not limited by the number of hogs that can be kept on a farm, but rather by the amount of manure those farms produce. To raise more pigs necessitates that a farmer transport more of the manure away from the farm. This creates a business opportunity, which I have leveraged by taking the swine manure and making asphalt out of it!

At the start of this, Dr. Elham Fini (the inventor of the manure-to-glue technology), Dr. Mahour Parast (President of Bio-Adhesive Alliance) and I relied on grants from the National Science Foundation. When oil prices rose, the price of asphalt more than doubled, thereby creating a need for a renewable asphalt substitute. Dr. Fini tested numerous raw materials: algae, sawdust, rice husks, corn stalks, even biofuel residue. Some ingredients produced poor yields. Others were too sticky or not sticky enough or the product burned up during a chemical reaction. We tried a bunch of different options, including making glue from trees and cow manure. Swine manure was the best at making glue; we found that it has a special oil that makes the glue stronger.

Our product improves the thermal properties of the asphalt, making it more durable and less likely to crack than typical asphalt. In addition, we give asphalt manufacturers more of a reason to use recycled materials, like swine manure. The basic process includes scooping up the manure at NC A&T and then using a process that combines the manure with heat and pressure in an oxygen-depleted water solution. It takes a total of 30 minutes to turn swine manure into glue for asphalt. Asphalt, also known as bitumen, is a sticky glue-like substance that is normally derived from petroleum and is used in road construction. We make asphalt without using petroleum, which is a derivative of crude oil. Our glue can potentially help the U.S. reduce dependence on foreign oil and has made for our best conversation-starter: “Let’s turn what stinks today into what sticks tomorrow.”

In 2013, we won the MassChallenge competition for $50K, the Megawatt Ventures competition for $100K, the ACC Clean Energy Challenge for $100K, and the National Clean Energy Business Plan Competition sponsored by the Department of Energy. We have done a lot of hard work to win these awards, and have tried to rely on organic fundraising rather than venture capital along the way.

What is next for your company?

These awards are helping us get up and running. Given that our product came from NC A&T, the university owns the patents, but we developed the technology and have exclusive rights for licensing.

The current world market for asphalt binder is $100 billion, the U.S. market is $16 billion, and our target is $7 billion of the U.S market. If our company converted all the manure generated each year here in the U.S., there could be $128 billion in revenue from diversifying into other high-end markets with applications for roofing, book binding, construction, and carpet, among other things. That is very exciting. I am currently learning the process of getting certification for these other applications so that we can get right to work. The commercialization stage will require significant capital. We won’t actually purchase property to host pigs. We will co-locate our reactors on already existing hog farms as a supplement to better manage their manure. Already, we have two farmers from large commercial hog farms willing to give us land to place our reactor on their farms.

Right now we are raising funds for our pilot reactor as part of the scale up process to our big commercial reactor. The asphalt industry is interested and we currently have two pre-buy letters of intent, one of them is for 90,000 tons of swine asphalt a year. If those get finalized, we will definitely need to scale up with a larger reactor while pursuing other applications of processed swine manure.

How do you balance starting up a company while in school? Any advice for future entrepreneurs?

I balance many different responsibilities which can be hectic at times, but I am really thankful for the opportunity to be a part of each one of them. My faith is definitely the ultimate driving factor for everything I do in life. Not only do I work in the manure business, but I am also a graduate student, an intern at my local church, and perform research on the side. I have had to keep the goal right in the center of my mind and be patient. Everybody wants to make money, but I want to make money and also help people. Our product has applications all around the world. I recently read a story about a hog farm in Chile that had to close down because the farm had so many pigs and the manure could not be properly managed. This was causing a grave situation as the manure began to contaminate water in the nearby valley, presenting a danger to the population. Bio-Adhesive Alliance can help take swine manure away from places suffering from such problems, and use it to make roads in places that don’t have roads.

The real question is: What else can we take that is viewed as worthless... and make a difference with it? Keep this in mind.

[This article is part of a series of OSTP blog posts celebrating the month of November as National Entrepreneurship Month.]

Douglas Herrin is a Student Volunteer at OSTP